Cookie

This website requires cookies to provide all of its features. For more information on what data is contained in the cookies, please see our Privacy Policy page. To accept cookies from this site, please click the Accept button below.

This website requires cookies to provide all of its features. For more information on what data is contained in the cookies, please see our Privacy Policy page. To accept cookies from this site, please click the Accept button below.

SKI TRAB BEGAN AS A PASSION PROJECT FOR GIACOMO TRABUCCHI, WHO IN 1946, IN A FLASH OF INTUITION, BUILT HIS FIRST PAIR OF SOLID WOOD SKIS. OUR FACTORY IS IN BORMIO, A WELL-KNOWN SKI RESORT AND HOME TO MANY SPORTING CHAMPIONS AND MOUNTAIN PROFESSIONALS. SURROUNDED AS WE ARE BY SO MANY EXPERT SKI TOURERS, WE HAVE ALWAYS BEEN ABLE TO CREATE PRODUCTS THAT GENUINELY MEET THEIR NEEDS.

BORMIO IS NOT JUST THE MOUNTAIN VILLAGE WHERE SKI TRAB SKIS ARE MADE.

“MADE IN BORMIO” MEANS THAT A PRODUCT WAS DESIGNED, DEVELOPED AND BUILT BY A COMPANY AND BY PEOPLE WHO ARE EXPERTS ON EVERYTHING TO DO WITH MOUNTAINS AND SKI TOURING. ALL SKI TRAB PRODUCTS ARE FRUIT OF THE EXPERIENCE, EXPERTISE AND KNOWLEDGE GAINED IN ALMOST 80 YEARS OF SKIING, LIVING AND WORKING IN THE MOUNTAINS. HERE AT SKI TRAB, WE UNDERSTAND THE SPORT, SPIRIT AND CULTURE OF SKIING—WE LIVE IT EVERY DAY. JOIN US ON OUR EPIC SKI TOURING MISSION AND EXPERIENCE FOR YOURSELF THE BEST TOURING SKIS OUT THERE.

MAKING HISTORY IN 1970, WE LAUNCHED OUR FIRST PAIR OF TOURING SKIS, MARKING A SIGNIFICANT MOMENT IN THE HISTORY OF OUR COMPANY.

SINCE THEN, WE HAVE HAD THE PRIVILEDGE OF BEING PART OF THE EVOLUTION OF THE SPORT, MAKING STATE-OF-THE-ART PRODUCTS DESIGNED TO BE LIGHTWEIGHT, RELIABLE AND EXCEPTIONALLY HIGH QUALITY, AND CEMENTING OUR REPUTATION AS SKI TOURING PIONEERS.

WE HAVE ALWAYS HAD A STRONG PRESENCE ON THE SKIMO RACING CIRCUIT.

THE SKI TRAB TEAM IS NUMBER ONE IN THE WORLD, WINNING THE MOST MEDALS ACROSS ALL EVENTS IN THE LAST TEN YEARS.

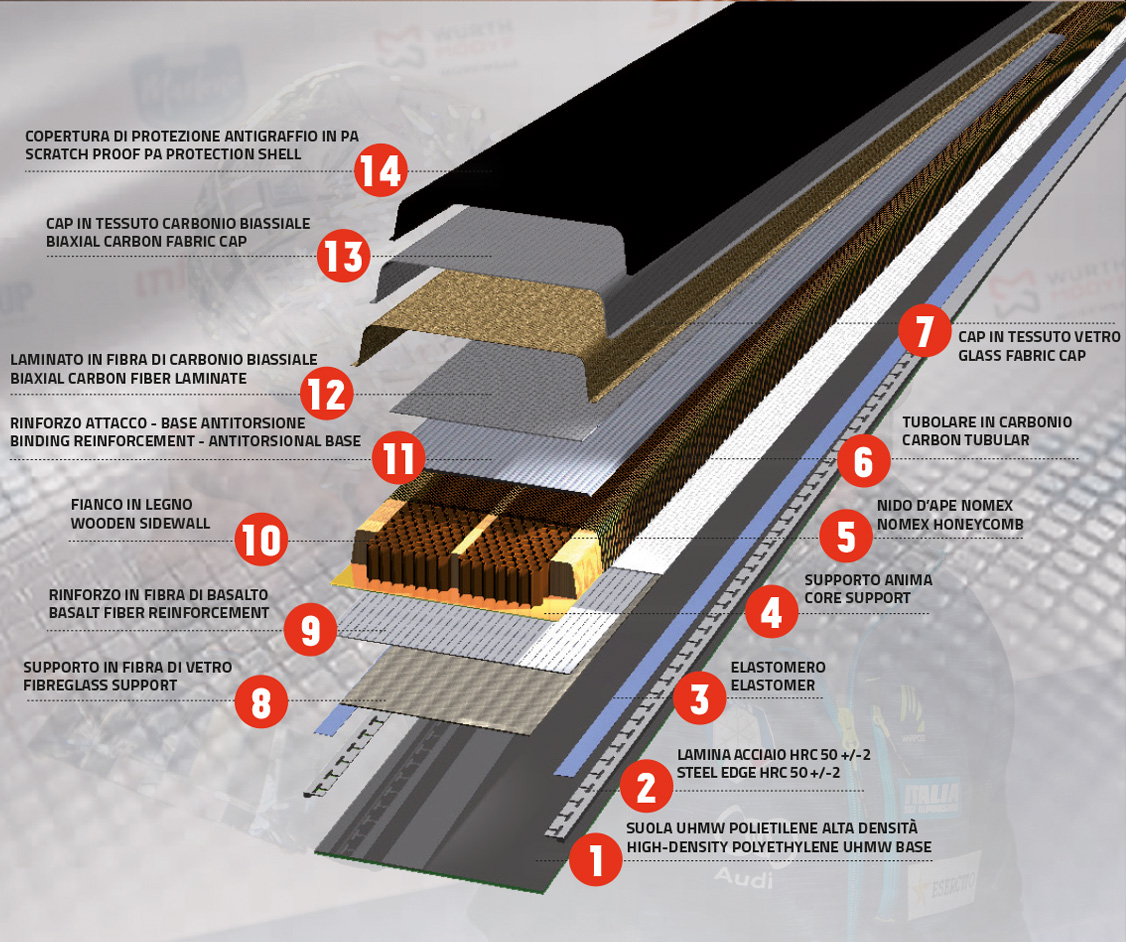

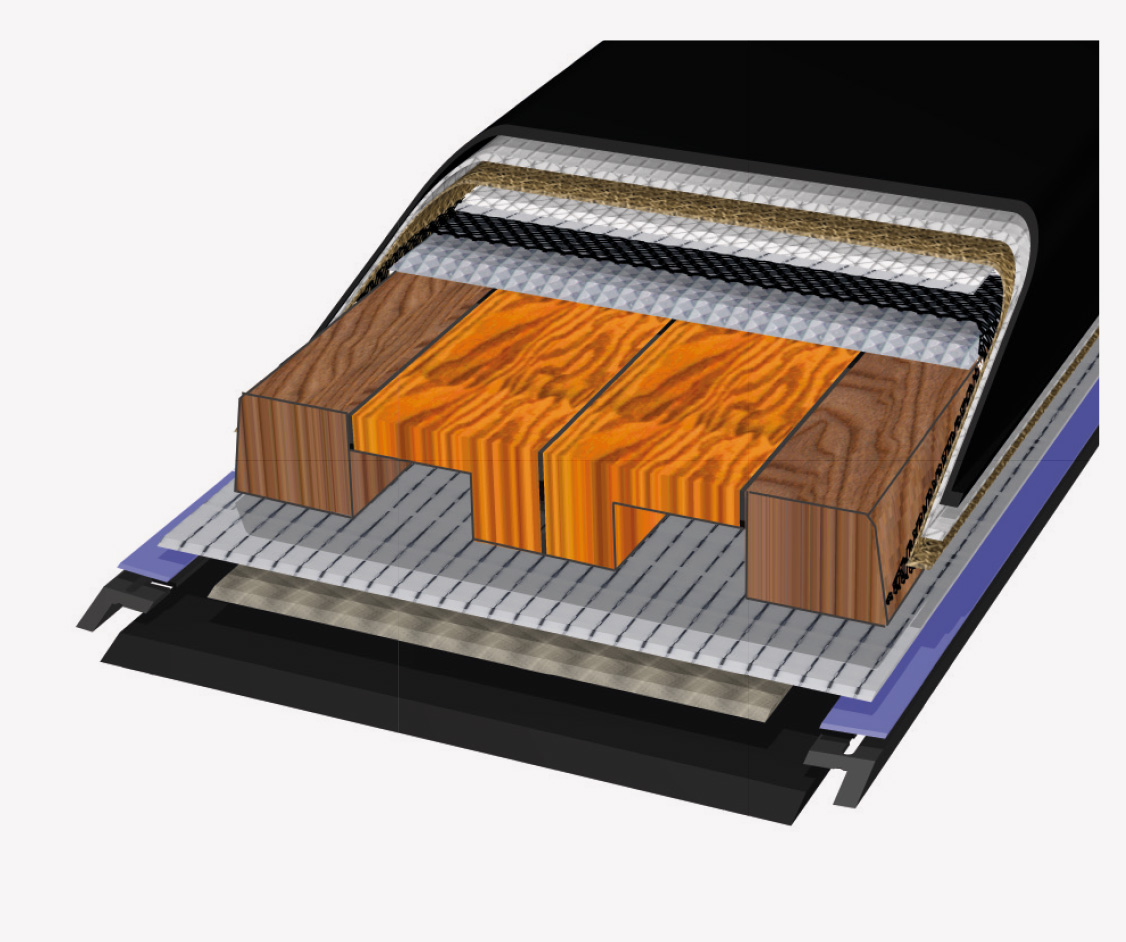

WE HAVE DEVELOPED A LIGHTWEIGHT TECHNOLOGY WITH 14 LAYERS ALLOWING US TO MODEL THE STRUCTURE OF THE SKI TO OUR EXACT REQUIREMENTS.

A PRODUCTION PROCESS THAT USES AN ULTRALIGHT CORE WHILE ALSO PROVIDING MAXIMUM ANTI-TORSIONAL STRENGTH.

14 INDIVIDUAL LAYERS WRAP THE CORE TO REACH THE DESIRED FLEX VALUES WITHOUT COMPROMISING THE STABILITY, TORSIONAL FLEXIBILITY AND DURABILITY OF THE SKI IN ANY WAY.

ARAMID IS A SYNTHETIC FIBER USED IN AEROSPACE AND MILITARY APPLICATIONS FOR ITS INCREDIBLE STRENGTH AND RESISTANCE. OUR LIGHTWEIGHT ARAMID HONEYCOMB CORE IS THE BEST ON THE MARKET IN TERMS OF STRENGTH-TO-WEIGHT RATIO, PROVIDING LONG-LASTING STABILITY, PERFORMANCE AND DURABILITY.

FOR A LIGHTWEIGHT, POWERFUL, DURABLE SKI.

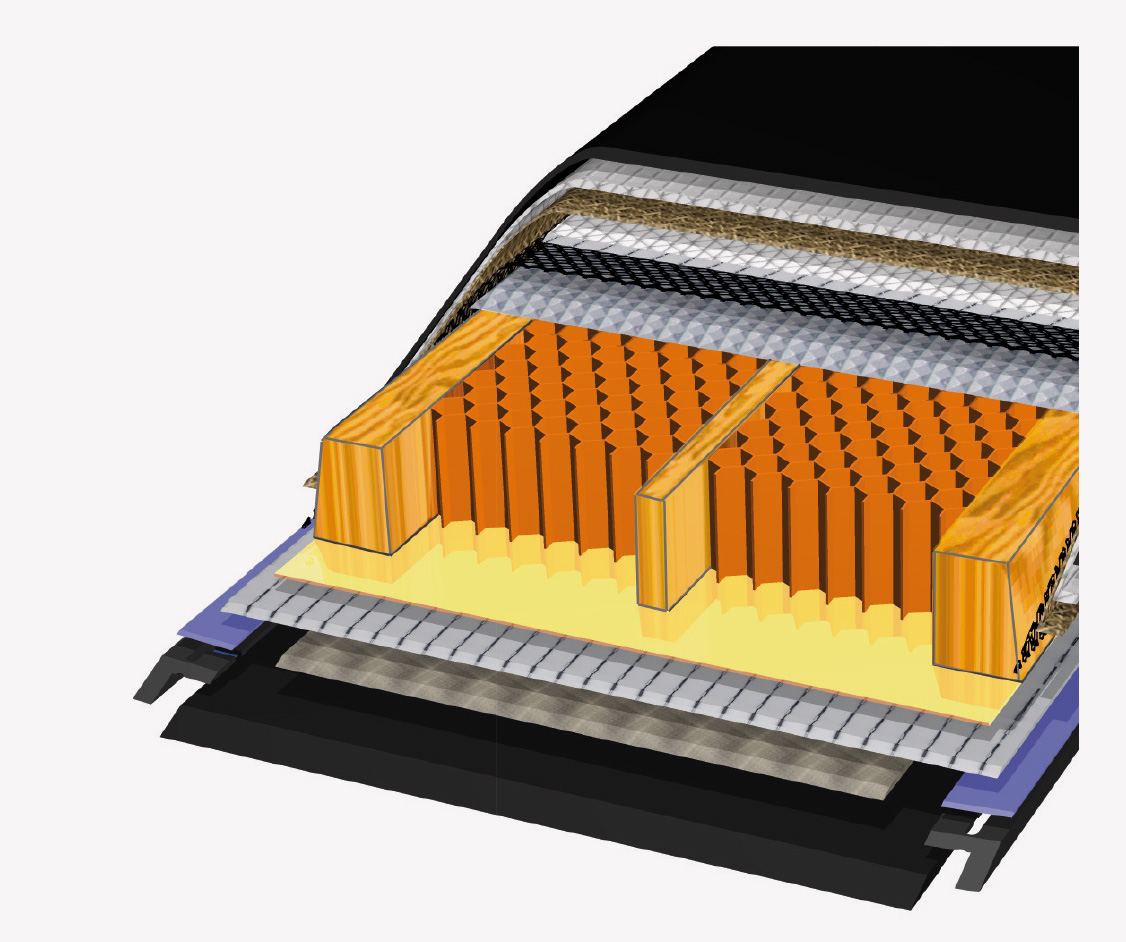

WOOD IS THE MOST USED RAW MATERIAL IN SKI PRODUCTION. FOR YEARS DESIGNERS HAVE TRIED TO FIND ONE THAT IS LIGHTWEIGHT YET DURABLE AND STRONG, BUT IT’S IMPOSSIBLE TO FIND ALL THESE QUALITIES IN ONE TYPE OF WOOD.

A LIGHTWEIGHT WOOD CORE NEEDS TO BE PROPERLY PROCESSED AND BLENDED WITH OTHER TYPES OF WOOD TO IMPROVE ITS STRENGTH. IT’S THEN WRAPPED IN COMPOSITE MATERIALS WHICH PROVIDE TORSIONAL RIGIDITY AND DURABILITY. THE AIR DUCTS MAKE THE SKI LIGHTER WITHOUT COMPROMISING THE STRUCTURE.

FOR OVER 70 YEARS WE HAVE DESIGNED, DEVELOPED AND BUILT OUR SKIS WITH PASSION AND DEDICATION.

IN BORMIO, WHERE THEY ARE THEN TESTED, REFINED AND ALWAYS WELL LOVED.

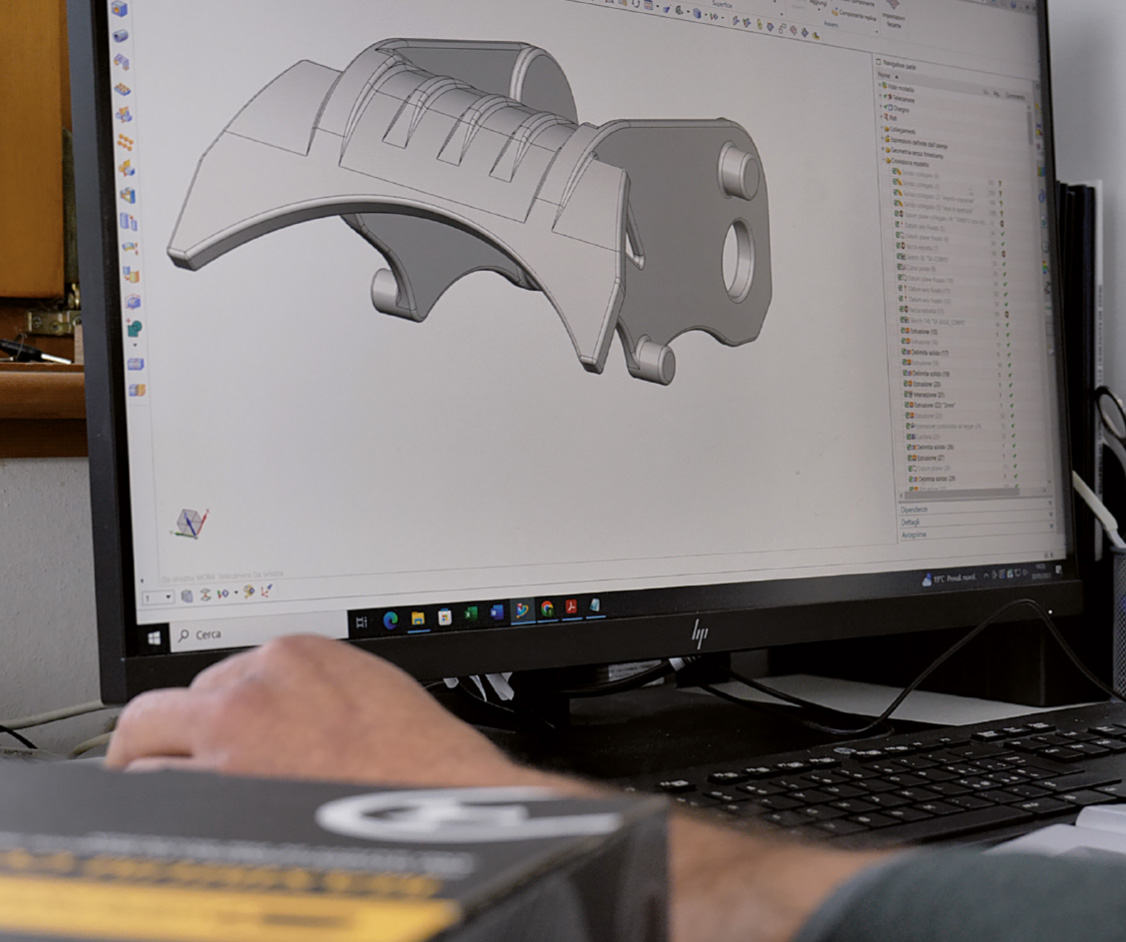

WE DEVELOP NEW, CUTTING-EDGE PROJECTS, INTEGRATING TECHNOLOGICALLY ADVANCED METHODS, CRAFTSMANSHIP, DESIGN AND MAXIMUM ATTENTION TO DETAIL, AS WELL AS INPUT FROM THE BEST MOUNTAIN PROFESSIONALS.

WE HAVE THE EXPERIENCE AND FACILITIES TO BUILD COMPLEX CONSTRUCTIONS LIKE OUR EXCLUSIVE 14-LAYER LIGHTWEIGHT TECHNOLOGY.

SKI TRAB: PASSION AND PERFORMANCE, DURABILITY AND RELIABILITY.

WE DON’T JUST STICK TO SKIS. OUR IDEAS, PATENTS AND INNOVATIONS ALSO GO INTO MAKING BINDINGS AND ACCESSORIES.

SOME OF OUR GROUNDBREAKING DESIGNS INCLUDE THE TITANIUM CORE FOR LIGHTWEIGHT SKITOURING BINDINGS AND THE TR1’S LATERAL TOE RELEASE, A NOVELTY IN THE WORLD OF FREETOURING.